EXPERIENCE A SMOOTHER RIDE

THE DIFFERENCE BLEW MY MIND

What our Customers Say - Discover How Strutmasters Made a Difference

FEATURED PRODUCTS

WE HAVE OVER 3500

APPLICATIONS

VIDEOS

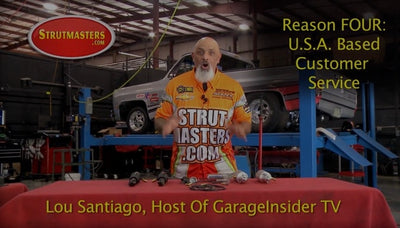

Learn Four Reasons to Choose Strutmasters

Recent Uploads

2015-2021 Mercedes-Benz C400 Rear Suspension Conversion Kit Installation

2015-2021 Mercedes-Benz C400 Front Suspension Conversion Kit Installation

2015-2018 Mercedes-Benz C 350e Rear Suspension Conversion Kit Installation

2015-2018 Mercedes-Benz C 350e Front Suspension Conversion Kit Installation

Why Purchase a Strutmasters Conversion Kit

Strutmasters GM Truck and SUV Suspension Conversion Kit on Truck U

X